IoT remote asset monitoring is revolutionizing how businesses manage their assets, from tracking equipment in real-time to predicting maintenance needs. By harnessing the power of interconnected devices, sensors, and data analytics, organizations can gain unprecedented visibility into their assets, leading to significant improvements in efficiency, productivity, and profitability.

Table of Contents

This technology is transforming industries across the globe, from manufacturing and logistics to energy and healthcare. By leveraging data collected from sensors deployed on assets, companies can gain valuable insights into their performance, identify potential issues before they arise, and optimize their operations in ways never before possible.

Deployment and Implementation Considerations

Deploying an IoT remote asset monitoring system requires careful planning and execution to ensure successful integration and optimal performance. The process involves several key steps, from selecting the right hardware and software components to addressing security concerns.

Hardware and Software Selection

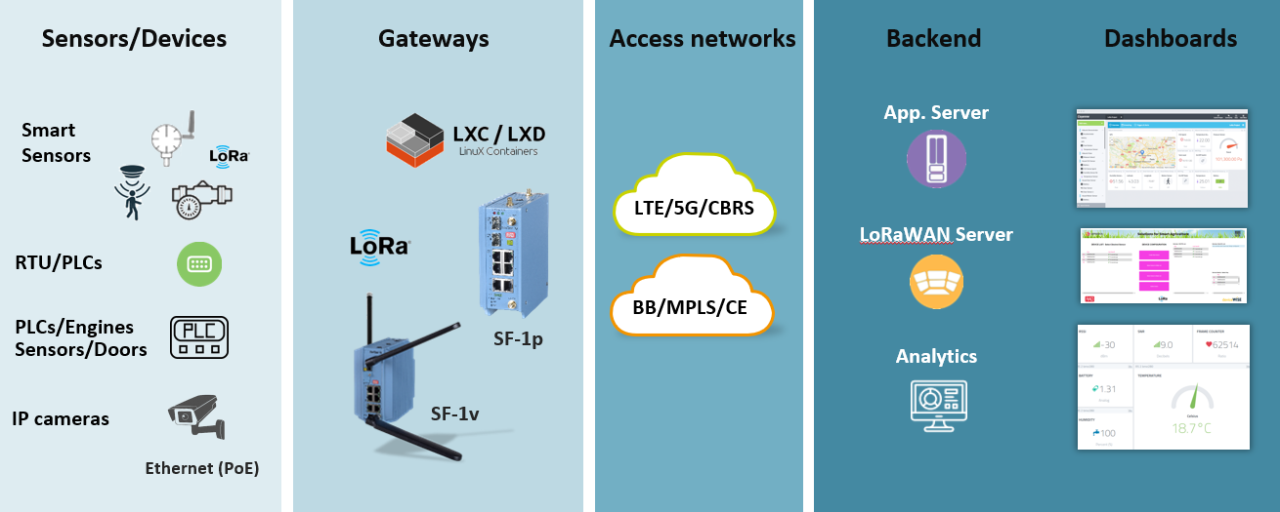

Choosing the right hardware and software components is crucial for building a reliable and efficient IoT remote asset monitoring system. This involves considering factors like:

- Asset Type and Location: Different assets have unique monitoring requirements. For example, a remote oil rig requires different sensors and data transmission capabilities compared to a fleet of delivery trucks.

- Data Collection Requirements: Determine the type of data you need to collect (temperature, pressure, vibration, etc.), the frequency of data collection, and the accuracy required.

- Network Connectivity: Consider the availability and reliability of network connectivity in the asset’s location. Factors like bandwidth, latency, and signal strength will influence your choice of communication protocols.

- Power Supply: Determine the power source for your sensors and data loggers. Options include batteries, solar power, or connection to the asset’s existing power supply.

- Scalability and Flexibility: Choose hardware and software that can be easily scaled and adapted as your monitoring needs evolve.

- Cost and Budget: Balance performance requirements with cost considerations to find the most cost-effective solution.

Security Implications and Best Practices

Security is paramount in IoT remote asset monitoring systems, as they handle sensitive data and control critical assets. Implementing robust security measures is essential to prevent unauthorized access, data breaches, and system disruptions.

- Data Encryption: Encrypt data in transit and at rest to protect it from unauthorized access. Use strong encryption algorithms like AES-256.

- Authentication and Authorization: Implement secure authentication mechanisms to verify user identities and restrict access to authorized personnel.

- Secure Communication Protocols: Utilize secure communication protocols like HTTPS and TLS to protect data transmitted over the network.

- Regular Security Updates: Keep your hardware and software up to date with the latest security patches to address vulnerabilities.

- Network Segmentation: Isolate your IoT network from other networks to minimize the risk of security breaches.

- Access Control: Implement access control mechanisms to limit access to sensitive data and system functions based on user roles and permissions.

- Data Backup and Recovery: Regularly back up your data and ensure you have a reliable recovery plan in case of data loss or system failure.

Key Features and Capabilities: Iot Remote Asset Monitoring

IoT remote asset monitoring offers a suite of powerful features that enable businesses to gain real-time insights into their assets, optimize operations, and make data-driven decisions. This section explores the key features and capabilities of this technology, providing a comprehensive overview of its benefits.

Real-Time Data Monitoring and Alerting

Real-time data monitoring is a core feature of IoT remote asset monitoring. This allows businesses to continuously track key asset parameters, such as temperature, pressure, vibration, and location, providing a comprehensive understanding of their assets’ performance and health.

The ability to set up alerts based on predefined thresholds is crucial for proactive asset management. When an asset deviates from its normal operating range, the system can trigger alerts, notifying relevant personnel immediately. This enables timely intervention and prevents potential problems from escalating.

- Continuous Monitoring: Sensors collect data from assets at regular intervals, providing a continuous stream of information about their performance.

- Data Visualization: Dashboards and reports present data in a clear and concise manner, allowing users to easily identify trends and anomalies.

- Customizable Alerts: Users can configure alerts based on specific thresholds or conditions, ensuring that they are notified of critical events in a timely manner.

Predictive Maintenance and Anomaly Detection

Predictive maintenance leverages historical data and machine learning algorithms to anticipate potential equipment failures before they occur. By analyzing patterns in sensor data, the system can identify early warning signs of wear and tear, allowing for scheduled maintenance before a breakdown occurs. This proactive approach minimizes downtime, reduces maintenance costs, and improves overall asset reliability.

Anomaly detection is another crucial aspect of predictive maintenance. By identifying unusual patterns in sensor data, the system can flag potential issues that might not be immediately apparent. This allows for early intervention and prevents minor problems from escalating into major failures.

- Machine Learning Algorithms: Advanced algorithms analyze historical data to identify patterns and predict future equipment behavior.

- Anomaly Detection: The system flags unusual data points that deviate from normal operating patterns, indicating potential issues.

- Maintenance Scheduling: Predictive maintenance insights allow for proactive scheduling of maintenance activities, reducing downtime and optimizing asset performance.

Remote Control and Asset Management

Remote control capabilities enable businesses to manage their assets from anywhere in the world. This includes features such as remote configuration, software updates, and even the ability to remotely shut down or restart equipment. This eliminates the need for on-site visits for routine tasks, saving time and resources.

Asset management functionalities allow businesses to track the location, condition, and usage of their assets. This comprehensive overview enables better inventory management, optimized asset utilization, and improved decision-making regarding asset deployment and allocation.

- Remote Configuration: Adjust asset settings and parameters remotely, eliminating the need for on-site visits.

- Software Updates: Deploy software updates and patches remotely, ensuring that assets are always running the latest version.

- Remote Control: Turn assets on or off, restart them, or perform other actions remotely, providing greater flexibility and control.

- Asset Tracking: Monitor the location, condition, and usage of assets in real-time, enabling efficient inventory management and asset optimization.

Case Studies and Success Stories

IoT remote asset monitoring has proven its value in various industries, resulting in significant improvements in efficiency, cost savings, and operational excellence. Examining real-world examples of successful implementations provides valuable insights into the benefits and challenges of this technology.

Examples of Successful Implementations

Here are some examples of successful implementations of IoT remote asset monitoring:

- Fleet Management: A large transportation company deployed IoT sensors on its fleet of trucks to monitor fuel consumption, engine performance, and driver behavior. The real-time data collected enabled the company to optimize routes, reduce fuel costs, and improve driver safety. This resulted in a 10% reduction in fuel consumption and a 5% decrease in maintenance costs.

- Manufacturing: A manufacturing plant implemented IoT sensors on its machinery to monitor equipment health, predict maintenance needs, and optimize production processes. The data collected allowed the plant to reduce downtime by 20%, improve production efficiency by 15%, and extend the lifespan of equipment.

- Healthcare: A hospital deployed IoT sensors on medical equipment to monitor their performance and ensure patient safety. The real-time data collected enabled the hospital to detect potential equipment failures before they occurred, reducing the risk of medical errors and improving patient outcomes.

Impact of Implementations on Business Outcomes

IoT remote asset monitoring has had a significant impact on business outcomes, including:

- Increased Efficiency: By providing real-time data on asset performance and utilization, IoT remote asset monitoring helps organizations optimize operations and improve efficiency. This can lead to reduced downtime, increased productivity, and faster turnaround times.

- Cost Savings: IoT remote asset monitoring can help organizations save money by reducing maintenance costs, minimizing waste, and optimizing resource allocation. By predicting maintenance needs, organizations can schedule repairs proactively, preventing costly breakdowns and downtime.

- Improved Safety: IoT remote asset monitoring can help improve safety by detecting potential hazards and risks in real-time. This can be particularly beneficial in industries where safety is paramount, such as transportation, manufacturing, and healthcare.

- Enhanced Decision Making: By providing a comprehensive view of asset performance and operational data, IoT remote asset monitoring empowers organizations to make more informed decisions. This can lead to better resource allocation, more effective risk management, and improved overall business performance.

Key Learnings and Best Practices

Here are some key learnings and best practices from successful IoT remote asset monitoring implementations:

- Define Clear Goals and Objectives: Before embarking on an IoT remote asset monitoring project, it is essential to define clear goals and objectives. This will help ensure that the project is aligned with the organization’s overall business strategy and that the chosen solution meets the specific needs of the business.

- Select the Right Technology: There are many different IoT technologies available, and it is important to choose the right one for the specific application. Factors to consider include the type of data being collected, the required level of accuracy, the communication infrastructure, and the budget.

- Develop a Robust Data Management Strategy: IoT remote asset monitoring generates a significant amount of data, and it is essential to have a robust data management strategy in place. This includes data storage, security, analysis, and visualization.

- Ensure Data Security and Privacy: Data security and privacy are critical considerations in any IoT project. Organizations must ensure that sensitive data is protected from unauthorized access and that all data handling practices comply with relevant regulations.

- Foster Collaboration and Communication: Successful IoT remote asset monitoring projects require strong collaboration and communication between IT, operations, and other relevant departments. This will help ensure that the project is implemented effectively and that the data collected is used to drive meaningful business outcomes.

Cost-Benefit Analysis

Implementing IoT remote asset monitoring involves a range of costs, but the potential benefits and return on investment can be significant. This section delves into the key cost factors, analyzes the potential benefits, and examines the factors influencing the cost-benefit analysis.

Cost Factors

The costs associated with implementing IoT remote asset monitoring can be categorized into several key areas:

- Hardware Costs: This includes the cost of sensors, gateways, and other hardware components needed to collect and transmit data. The cost of these components can vary depending on the specific application and the type of sensors required.

- Software Costs: This includes the cost of software platforms for data acquisition, analysis, and visualization, as well as any specialized software for specific applications. The cost of software can vary depending on the features and functionality required.

- Installation and Integration Costs: This includes the cost of installing and configuring the hardware and software components, as well as integrating the system with existing IT infrastructure. The cost of installation and integration can vary depending on the complexity of the system and the expertise required.

- Maintenance and Support Costs: This includes the cost of ongoing maintenance, software updates, and technical support. The cost of maintenance and support can vary depending on the size and complexity of the system.

- Connectivity Costs: This includes the cost of cellular or satellite communication services required to transmit data from remote assets. The cost of connectivity can vary depending on the location of the assets, the amount of data transmitted, and the type of communication service used.

Potential Benefits and Return on Investment, Iot remote asset monitoring

IoT remote asset monitoring offers a wide range of potential benefits, leading to significant return on investment (ROI). The key benefits include:

- Improved Asset Management: Real-time data provides insights into asset performance, allowing for proactive maintenance and reduced downtime. This can lead to significant cost savings and improved operational efficiency.

- Enhanced Safety and Security: Remote monitoring enables early detection of potential safety hazards or security breaches, allowing for timely intervention and mitigating risks.

- Optimized Operations: Data-driven insights can optimize operational processes, leading to improved resource allocation, reduced waste, and increased productivity.

- Reduced Costs: By minimizing downtime, preventing equipment failure, and optimizing resource utilization, IoT remote asset monitoring can significantly reduce operational costs.

- Improved Customer Service: Real-time asset tracking and monitoring can enhance customer service by providing faster response times and more accurate information.

Factors Influencing Cost-Benefit Analysis

The cost-benefit analysis of IoT remote asset monitoring is influenced by several factors:

- Asset Value and Criticality: The higher the value and criticality of the asset, the greater the potential benefits and return on investment.

- Operational Efficiency: The potential for improving operational efficiency through remote monitoring is a key factor in the cost-benefit analysis.

- Risk Mitigation: The ability to mitigate risks through early detection and intervention is a significant benefit that can justify the cost of implementation.

- Industry and Application: The specific industry and application of IoT remote asset monitoring can influence the costs and benefits associated with the technology.

- Scalability and Flexibility: The scalability and flexibility of the solution are important factors to consider, as they can impact the long-term cost-effectiveness of the system.

Final Wrap-Up

As IoT remote asset monitoring continues to evolve, its impact on businesses and industries will only grow. With advancements in sensor technology, data analytics, and artificial intelligence, we can expect even more sophisticated and powerful solutions in the future. By embracing this transformative technology, organizations can unlock new levels of operational efficiency, improve decision-making, and ultimately gain a competitive edge in today’s dynamic marketplace.

IoT remote asset monitoring relies on reliable data transmission, and sometimes that means creating bootable USB drives for specific tasks. If you need a tool to create bootable USB drives, Rufus USB is a popular and free option. This software can help you prepare USB drives for various purposes, including installing operating systems or deploying IoT devices, ensuring your asset monitoring system functions smoothly.